Introduction

The global chemical industry is a cornerstone of modern manufacturing, and within its vast ecosystem, boron derivatives like boric acid play a surprisingly pivotal role. As a versatile, inorganic compound, boric acid (H3BO3) is integral to a multitude of sectors, from high-tech electronics and advanced glass to agriculture and pharmaceuticals. Its significance is particularly pronounced in the dynamic economic landscape of Asia, a region characterized by rapid industrialization, technological advancement, and massive manufacturing output. Singapore, with its strategic location, world-class logistics, and robust regulatory framework, has emerged as a critical hub for the chemical trade in the region.

This article delves deep into the world of boric acid and the broader boron industry, with a focused lens on Asia and Singapore. We will explore the fundamental properties and production methods of this essential chemical, examine its diverse and critical applications, analyze current market trends, and discuss the vital role of professional chemical suppliers. Companies like Chemtradeasia exemplify the expertise required to navigate this complex market, ensuring a reliable supply of high-quality boron products to fuel industrial growth and innovation across the continent.

Understanding Boric Acid: Properties and Production

Boric acid is a weak, monobasic Lewis acid of boron that appears as a white, crystalline powder or colorless flakes. It is odorless and has a slightly acidic and bitter taste. The compound is soluble in water, and its solubility increases significantly with temperature. Chemically, it is known for its mild antiseptic, antifungal, and flame-retardant properties. These inherent characteristics stem from its ability to form ester complexes with hydroxyl groups in organic compounds, a trait that underpins many of its industrial uses. It is important to distinguish boric acid from its raw material source, borax (sodium borate), though they are part of the same boron value chain.

The primary production of boric acid involves reacting borax (sodium tetraborate) with a strong mineral acid, such as hydrochloric or sulfuric acid. The process yields boric acid and a sodium salt byproduct. Another significant source is from the processing of colemanite and other boron-containing ores. Major global reserves of boron minerals are concentrated in a few regions, notably Turkey and the United States. This geographical concentration makes the global supply chain a critical consideration for downstream industries worldwide. The final product is graded based on purity, crystal size, and heavy metal content, with specifications tailored for specific end-uses, such as electronic grade for semiconductors or high-purity grade for pharmaceutical applications.

Key Industrial Applications of Boric Acid

The utility of boric acid spans traditional heavy industry to cutting-edge technology. Its most prominent application is in the manufacture of glass and fiberglass. In borosilicate glass (e.g., Pyrex), boric acid acts as a flux, lowering the melting temperature and thermal expansion coefficient, resulting in glass that is resistant to thermal shock and chemical corrosion. This is essential for laboratory glassware, kitchenware, and high-intensity lighting. In fiberglass insulation and reinforcement, boron provides durability and flame resistance. The ceramics industry also relies heavily on boric acid in the production of glazes, frits, and enamels, where it enhances finish durability, gloss, and color stability.

Beyond traditional materials, boric acid is a workhorse in flame retardants. When added to cellulose insulation, plastics, and textiles, it releases water vapor when heated, diluting flammable gases and forming a protective glassy layer that inhibits oxygen access. In agriculture, it serves as an essential micronutrient fertilizer, correcting boron deficiencies in soils that can lead to poor crop yield and quality. Furthermore, its mild antiseptic properties make it valuable in medical disinfectants, eye washes, and wood preservation solutions. Emerging applications are found in lithium-ion battery electrolytes and as a neutron absorber in nuclear power plants, highlighting its role in future energy technologies.

The Asian and Singaporean Boron Market Landscape

The Asia-Pacific region dominates the global consumption of boric acid, driven by its massive manufacturing base. China, India, Japan, and South Korea are the largest consumers, with demand fueled by booming construction (requiring fiberglass and insulation), automotive production (requiring glass and flame-retardant materials), and electronics manufacturing. The region's push towards food security also underpins steady demand in the agricultural sector. Market trends indicate a growing preference for high-purity grades to support advanced electronics and pharmaceutical production, reflecting the region's move up the value chain.

Singapore plays a unique and strategic role in this landscape. While not a major producer, it is a premier trading and distribution hub for chemicals in Southeast Asia. Its world-class port, free trade policies, and stringent safety and quality standards make it an ideal gateway for chemical imports and exports. Many multinational chemical corporations and regional distributors, including entities like Chemtradeasia, base their Asia-Pacific operations in Singapore. They leverage the country's infrastructure to supply high-quality boric acid and other boron derivatives to manufacturers across Malaysia, Indonesia, Thailand, and Vietnam, ensuring just-in-time delivery and consistent quality for diverse industrial needs.

Sourcing Boric Acid: The Role of Suppliers like Chemtradeasia

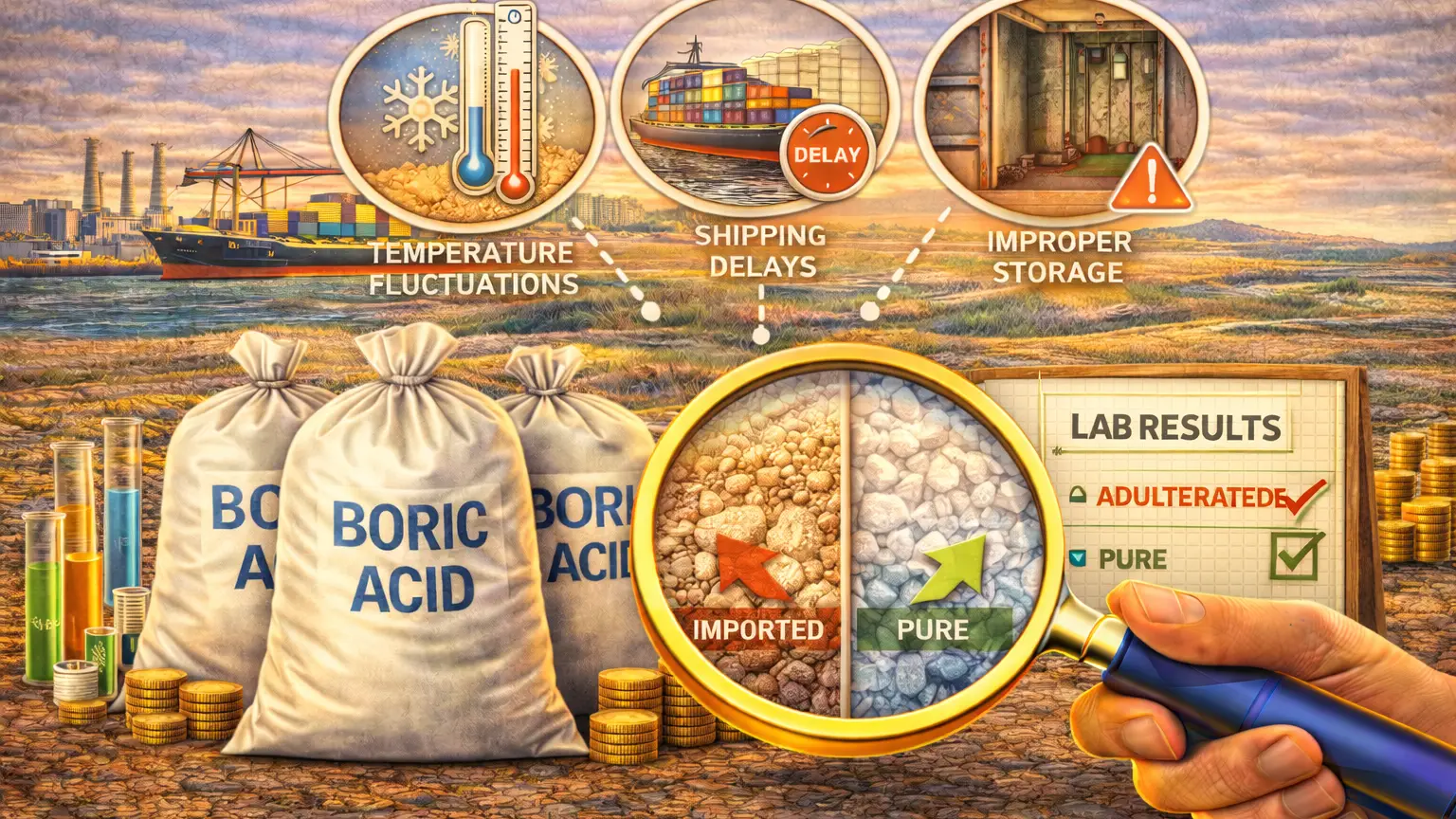

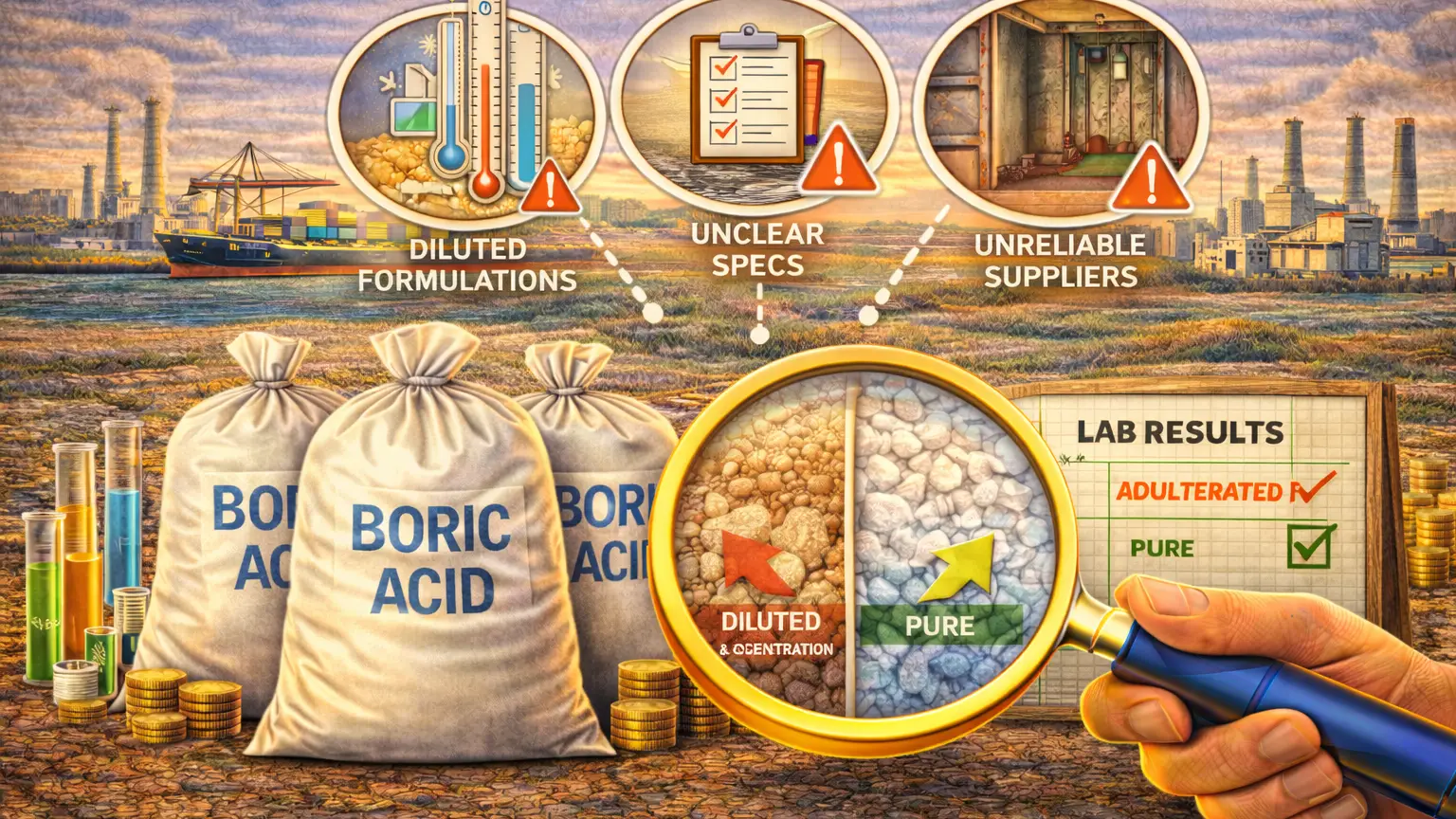

Reliable sourcing of industrial chemicals like boric acid is not merely a procurement task; it is a strategic business function. Challenges include supply chain volatility, quality consistency, regulatory compliance (such as REACH, GHS, and local regulations), and logistical complexity. This is where specialized chemical suppliers provide immense value. A reputable supplier acts as a partner, offering more than just a product. They provide technical data sheets (SDS), certificates of analysis, and application expertise to help clients select the correct grade, be it technical, USP, or electronic grade, for their specific process.

Companies operating in the model of Chemtradeasia exemplify this integrated approach. They typically manage the entire logistics chain, from sourcing directly from major producers to handling warehousing, packaging (from bulk bags to smaller drums), and insured transportation. For buyers in Asia, partnering with a Singapore-based supplier offers distinct advantages: access to a diversified portfolio of global sources, mitigation of supply risk, adherence to international quality and safety protocols, and streamlined logistics across the region. This allows manufacturers to focus on their core competencies while trusting that their critical raw material supply is secure, compliant, and technically supported.

Future Outlook and Sustainability in the Boron Industry

The future demand for boric acid is projected to remain robust, closely tied to global megatrends. Urbanization and infrastructure development in emerging Asia will continue to drive demand in construction materials. The global shift towards electric vehicles and renewable energy systems will increase need for fiberglass in wind turbine blades and boron compounds in battery technology. Furthermore, advancements in biotechnology and medicine may open new avenues for boron-based compounds in drug delivery and treatment. However, the industry also faces the imperative of sustainability.

Environmental and health considerations are shaping production and application practices. While boric acid has low toxicity compared to many alternatives, responsible handling and disposal are paramount. The industry is focusing on improving production efficiency to reduce energy consumption and waste. There is also a growing trend towards developing closed-loop systems in end-use applications, such as recycling borosilicate glass. Suppliers and end-users are increasingly aligned in ensuring that the entire lifecycle of boric acid, from responsible mining to safe transportation and application, adheres to the highest environmental, social, and governance (ESG) standards, ensuring the long-term viability of the boron sector.

Conclusion

Boric acid is far more than a simple chemical commodity; it is an enabler of modern industry and technological progress. Its unique properties make it indispensable in creating safer, stronger, and more efficient materials, from the glass in our smartphones to the insulation in our homes. The vibrant markets of Asia, supported by the logistical and commercial excellence of hubs like Singapore, are at the forefront of consuming and innovating with this versatile compound.

Navigating this complex market requires expertise and reliable partnerships. Success for manufacturers depends on securing a supply chain that is not only cost-effective but also quality-assured and compliant. By engaging with established and professional suppliers who understand both the technical nuances of boric acid and the dynamics of the Asian market, businesses can ensure they have the foundational materials needed to compete and thrive in an increasingly demanding global landscape. The boron industry, with boric acid as a key pillar, is poised for continued growth, driven by innovation and strategic supply chain management. For reliable sourcing, technical support, and competitive supply of boric acid and boron derivatives across Asia, connect with Chemtradeasia’s.

Leave a Comment