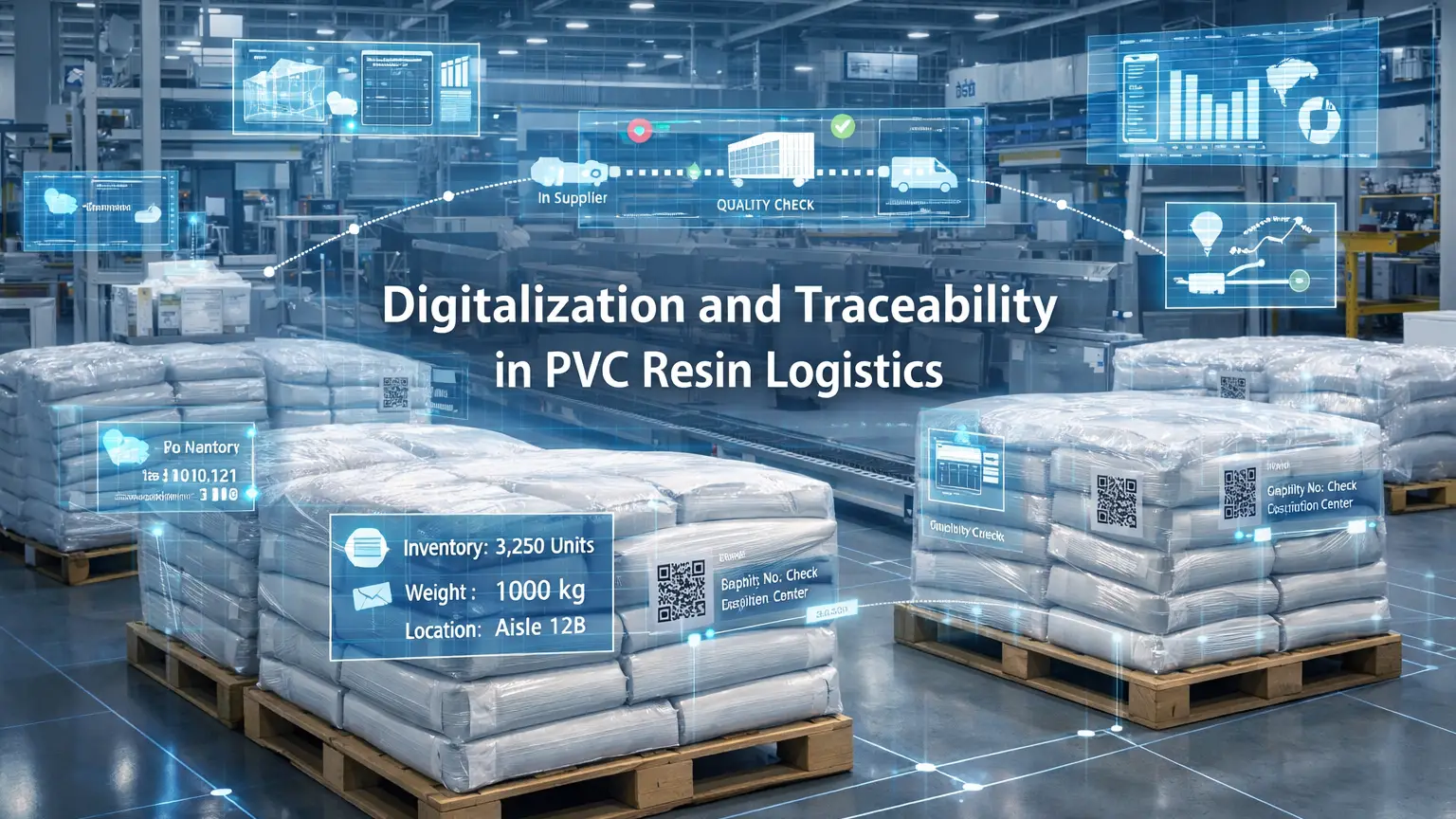

Digitalization and traceability are becoming core requirements in PVC resin logistics, not optional upgrades. As global PVC supply chains grow more complex, manufacturers, distributors, and converters face rising pressure to maintain product integrity, regulatory compliance, and delivery reliability across borders. Traditional paper-based tracking and manual coordination can no longer support the speed, transparency, and accountability expected in modern chemical logistics.

In response, PVC resin logistics is moving toward data-driven systems that provide real-time visibility, structured traceability, and integrated documentation from production to end use. This shift is reshaping how PVC resin is stored, transported, verified, and delivered worldwide.

Why PVC Resin Logistics Is Going Digital

PVC resin is sensitive to handling conditions. Exposure to moisture, contamination, or improper storage can compromise quality and downstream processing performance. At the same time, PVC supply chains often involve multiple transport modes, third-party warehouses, and international regulatory regimes.

Digitalization addresses these challenges by replacing fragmented records with connected platforms that capture and share logistics data automatically. This aligns with the broader move toward Logistics 4.0, where connected devices, cloud systems, and analytics enable smarter planning and faster response to disruption.

For PVC buyers and suppliers, digital logistics improves reliability, reduces operational risk, and supports compliance with tightening chemical regulations.

How PVC Resin Supply Chains Operate

PVC resin originates from petrochemical feedstocks such as ethylene dichloride and vinyl chloride monomer, which are polymerized into resin powder or pellets. From production plants, resin is packed in bags, big bags, or transported in bulk silos, then moved by truck, rail, or sea to distributors and converters.

Throughout this journey, logistics teams must manage batch segregation, dryness, cleanliness, and documentation accuracy. Because PVC grades differ by application and regulatory classification, traceable movement from origin to destination is essential. Digital systems allow these requirements to be monitored consistently across locations and partners.

What Digitalization Means in Chemical Logistics

Digitalization in PVC logistics refers to the use of integrated technologies that connect planning, execution, and monitoring activities into a single data environment. These systems typically combine enterprise platforms with real-time data capture tools.

Instead of relying on manual updates, logistics teams gain continuous visibility into inventory status, shipment location, and handling conditions. This allows faster decisions, better forecasting, and fewer disruptions when conditions change.

Why Traceability Matters for PVC Resin

Traceability is the ability to follow a specific batch of PVC resin through every stage of the supply chain. This includes production origin, batch number, storage history, transport conditions, and final delivery.

For PVC resin, traceability supports:

- quality assurance and batch verification

- fast and targeted recall management

- regulatory audits and compliance reporting

- prevention of cross-contamination or misallocation

Chemical regulations increasingly require detailed material tracking, and digital traceability systems make this information accessible and auditable without manual effort.

Key Digital Technologies Used in PVC Resin Logistics

Several technologies form the foundation of digital PVC logistics:

- ERP and cloud platforms centralize logistics, inventory, and documentation data, ensuring all stakeholders work from a single source of truth.

- IoT sensors and GPS devices monitor shipment location, humidity, and temperature in real time, helping teams detect risks such as moisture exposure early.

- RFID and track-and-trace tags automate identification of pallets, bags, or containers, reducing errors in receiving, picking, and dispatch.

- Blockchain-based ledgers are emerging for multi-party traceability, offering tamper-resistant records where supply chain actors need shared visibility without relying on a single controller.

Together, these tools convert logistics from a reactive process into a predictive, data-enabled system.

Improving Inventory Control and Demand Visibility

Digital inventory systems linked to real-time data allow PVC suppliers and distributors to manage stock more precisely. Instead of static inventory counts, planners can see which batches are available, how long they have been stored, and where they are located.

This visibility reduces stockouts, prevents overstocking, and supports smarter allocation of resin grades to customer demand. For high-volume materials like PVC, even small improvements in inventory accuracy can translate into meaningful cost savings.

Enhancing Transport Monitoring and Shipment Tracking

Digital shipment tracking improves reliability across domestic and international routes. GPS-enabled monitoring provides accurate estimated arrival times and alerts logistics teams when delays or route deviations occur.

Digital documentation further streamlines cross-border logistics by automating shipment records, customs paperwork, and quality certificates. This reduces manual errors, speeds up clearance, and minimizes delays at ports and terminals.

Supporting Regulatory Compliance Through Digital Records

Chemical logistics operates under evolving regulatory frameworks related to safety, environmental protection, and material traceability. Digital systems simplify compliance by generating structured, time-stamped records that can be retrieved instantly during audits or inspections.

Electronic safety data sheets, shipment histories, and batch records reduce the risk of non-compliance and help companies respond quickly to regulatory changes without reworking manual processes.

Reducing Risk and Protecting Product Integrity

Traceability systems also strengthen risk management. By maintaining a continuous digital record, companies can isolate affected batches if quality issues arise, rather than recalling entire shipments.

Digital authentication reduces the risk of counterfeit or off-spec resin entering the supply chain, protecting both brand reputation and customer trust. Automated condition monitoring also helps prevent quality degradation caused by moisture, improper storage, or handling deviations.

Integration Challenges and Practical Adoption

Despite the benefits, digitalization presents challenges. Legacy systems may not integrate easily with newer platforms, and cybersecurity becomes a concern as connectivity increases. Workforce training and process redesign also require investment.

Successful adoption often follows a phased approach. Companies typically start with high-impact areas such as RFID tagging in warehouses or condition monitoring for bulk transport, then expand as systems and teams mature.

What the Future Holds for PVC Resin Logistics

Looking ahead, digital PVC logistics will continue to evolve. Artificial intelligence and advanced analytics will support predictive routing and disruption management. Blockchain adoption may expand for recycled PVC and circular supply chains. Sustainability reporting will increasingly rely on digital traceability to link logistics data with ESG metrics.

These developments point toward logistics systems that are not only efficient, but also transparent, compliant, and resilient.

Conclusion

Digitalization and traceability are reshaping PVC resin logistics by delivering real-time visibility, stronger compliance, and improved operational control. In a market defined by global trade, regulatory scrutiny, and tight quality requirements, digital logistics provides the foundation for resilient and scalable supply chains.

For manufacturers and buyers, investing in digital traceability is no longer a future concept. It is a practical step toward reducing risk, improving service reliability, and supporting long-term growth.

If your organization is sourcing or distributing PVC resin across multiple markets, Chemtradeasia supports customers with transparent logistics coordination, documentation readiness, and reliable regional supply networks. Our experience in chemical distribution helps partners navigate complex logistics environments while maintaining quality and compliance from origin to delivery.

Leave a Comment